At this exact moment, the warehousing industry is at a very crucial juncture. The traditional methods of storing things are being scrutinized more closely as worries about the environment continue to grow and as regulations become more stringent. The need for long-term solutions is no longer a hushed remark in the background; rather, it is an urgent necessity. When it comes to this particular circumstance, push back racking systems shine like a light of hope because they are not only effective but also environmentally beneficial, which is precisely what can be said about green storage.

Can you tell me about racks that push back?

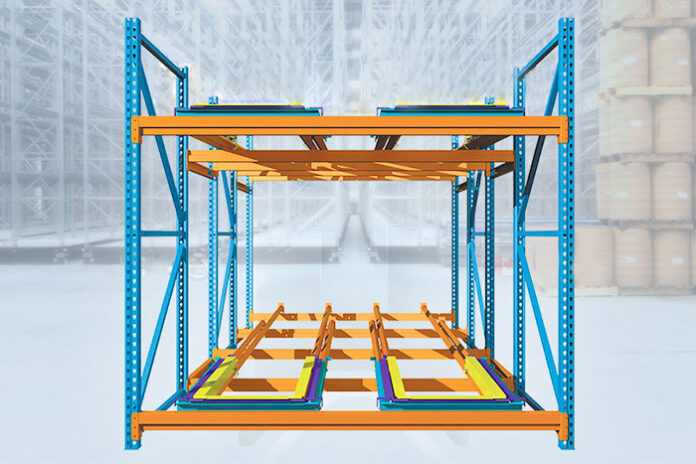

There is a new method of storing goods that makes use of gravity to keep track of inventory. This method is known as gravity flow racking, which is another term for push back racking systems. Pallets are placed directly on beams in the manner that is typical for pallet shelving. Push back shelving systems, on the other hand, make use of rollers or tracks that are at an inclined angle. Pallets situated below them gently push pallets that are on the highest level of the system backward. A storage arrangement that is dense and takes up minimal space is created as a result of this. The first-in, first-out (FIFO) method ensures that the inventory flow remains consistent whenever pallets are removed from the front of the system. This is accomplished by rolling the remaining pallets ahead automatically.

Is there a connection between push back shelf systems and environmentally responsible warehousing?

There is a strong correlation between the primary concepts of green storage and the numerous advantages that push back shelving systems offer. at order to reduce their impact on the environment, they implement the following measures at their warehouses:

1. Less consumption of electrical power:

Because push back racking systems are propelled by gravity, they reduce the number of forklift trips that are required inside the warehouse by a significant amount. This results in fewer forklift trips. This means that less energy is required, which in turn means that there are fewer carbon emissions and that operational costs are reduced.

Because push back racking systems are able to hold a large quantity of things, they are able to fit in a smaller warehouse space. This results in improved illumination. As a result of this, there is a reduced requirement for lighting in the space, which further reduces the amount of energy that is consumed.

2. A more efficient use of available space:

By utilizing the entire height of the warehouse, push back racking systems are able to store a greater quantity of items while simultaneously reducing the amount of space that is wasted. In this way, the area may be utilized more effectively, and the need to construct additional warehouses is reduced, which results in the conservation of resources.

An Improved Inventory Management System: The first-in, first-out (FIFO) inventory movement of push-back rack systems prevents products from becoming bad before they are supposed to be delivered. This results in a reduction in waste and an improvement in inventory management, both of which contribute to the improved environmental friendliness of the supply chain.

3. A more secure site of employment:

Push back racking systems require fewer forklifts, which means that the risk of accidents involving forklifts is lower. This is because push back racking systems are more efficient. Because of this, the warehouse is now a more pleasant environment for everyone to work to be.

The fact that push back racking systems are designed to function with gravity contributes to the fact that they are easier on the bodies of workers, hence lowering the amount of strain and fatigue that they experience. The employees will be healthier and more productive as a result of this.

4. The effectiveness of the materials:

The majority of push back shelf systems are constructed out of high-quality steel, which gives them a very sturdy and long-lasting construction compared to other types of shelving. This reduces the amount of materials that need to be replaced and the amount of damage that is caused to the environment by mass production and disposal of resources.

Because of their adjustable design, push back racking systems are simple to relocate and are able to accommodate more storage space when the requirements for storage change. Because of this, there is less of a need to purchase additional racks, which results in cost savings, conservation of resources, and a reduction in waste.

Utilizing a Holistic Method: There Are Benefits That Extend Beyond the Benefits

Despite the fact that push back racking systems are very beneficial to the environment, it is essential to keep in mind that sustainability in storage is an all-encompassing goal. It may be possible to make these strategies even more effective by using them in conjunction with other environmentally conscious plans. The following are some crucial factors to keep in mind:

- Lighting that consumes less energy: LED lighting solutions are a good choice because they consume less energy and require less maintenance than other types of lighting.

- When it comes to incorporating green energy, it is important to investigate the possibility of using solar panels, wind turbines, and other green energy sources to power the warehouse.

- Material Handling That Is Sustainable: The purchase of electric forklifts and other material handling equipment that consumes less gas is one way to reduce the amount of carbon pollution that is produced.

- The reduction of rubbish and recycling: In order to prevent waste from being dumped in landfills, it is important to implement effective waste management strategies such as composting and recycling programs.

As We Move Forward, What Does the Future Hold for Green Warehousing?

As the warehouse industry undergoes constant transformations, push back racking systems will become increasingly significant in the process of making the future more ecologically friendly. They are an excellent option for companies that are concerned about the environment because they make the most efficient use of space, consume less energy, and provide a safer working environment for employees. Through the implementation of these novel concepts and the dedication to a comprehensive strategy for green warehousing, we have the ability to construct a future in which efficiency and sustainability are inextricably linked. Because of this, the globe will become healthier, and the future will be more prosperous for the generations that come after us.

Take a step back, finally. Racked systems are more than just a means of storing things; they are a sign of growth and a statement of our collective resolve to care for the environment. Racking systems are a sign of growth. When combined with other environmentally conscious initiatives, they have the potential to make the warehousing business a frontrunner in terms of sustainability. In the future, this will pave the path for a future in which efficiency and environmental friendliness go hand in hand simultaneously.