Injection moulding services revolutionize plastic component production in modern manufacturing. The process offers cost-effective, high-quality results, with design flexibility for intricate geometries. It caters to high-volume production and customized designs, making it essential for meeting market demands and staying competitive in manufacturing.

The Advantages of Utilizing Injection Moulding Services for Your Manufacturing Needs

Benefits of injection moulding

These services offer several advantages for manufacturing needs. It is a cost-effective solution, particularly for high-volume production, resulting in economies of scale. The process ensures high-quality output with consistent part dimensions and surface finishes, meeting industry standards. With design flexibility, intricate and complex geometries can be created. Fast turnaround times reduce production lead times, enabling quicker product delivery. Overall, the benefits of injection moulding services enhance efficiency, product quality, and competitiveness for manufacturers in various industries.

Cost-effective production

Cost-effective production is a primary advantage of utilizing these services. With the ability to produce high volumes of parts in a single run, the process achieves economies of scale, reducing unit costs. It minimizes material waste and requires less manual labor compared to other manufacturing methods. Injection moulding’s efficiency and streamlined production contribute to significant cost savings, making it an ideal choice for businesses looking to optimize their manufacturing processes while delivering high-quality products at competitive prices.

High-quality output

High-quality output is a key advantage of injection moulding services. The process ensures consistent part dimensions and surface finishes, meeting strict quality standards. By using precise moulds and controlled parameters, manufacturers can achieve uniformity and accuracy in their products. Additionally, injection moulding minimizes defects and variations, resulting in reliable and durable components. The ability to produce high-quality output consistently enhances product performance, customer satisfaction, and brand reputation, making injection moulding a preferred choice for businesses seeking excellence in their manufacturing processes.

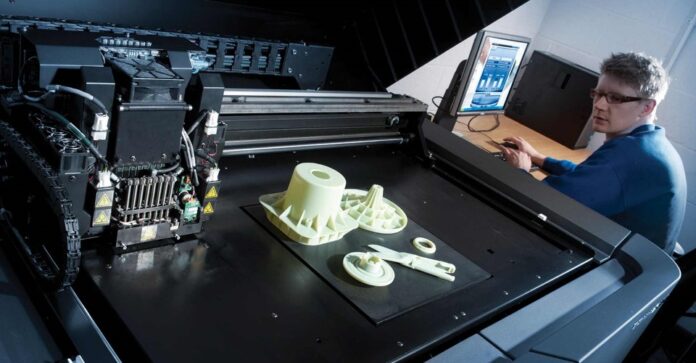

Design flexibility

Design flexibility is a significant advantage of these services. With the capability to produce custom moulds, manufacturers can bring innovative ideas to life with precision. Injection moulding accommodates various shapes, sizes, and features, enabling the development of unique and functional products. This flexibility empowers businesses to stay competitive, adapt to market demands, and deliver tailored solutions to meet specific customer needs.

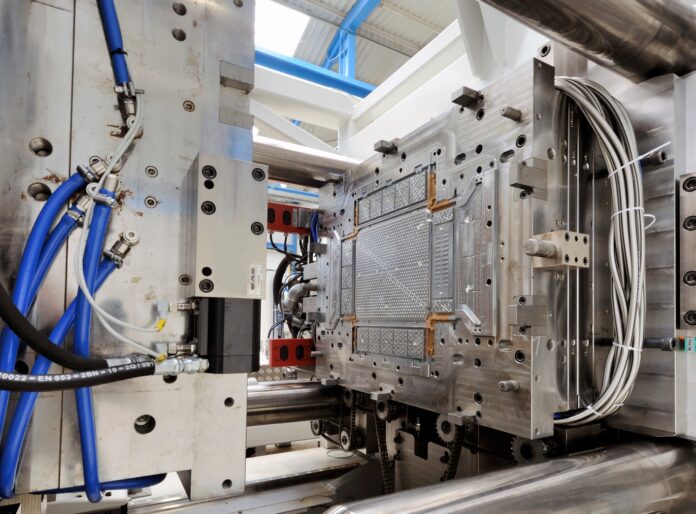

Fast turnaround time

Fast turnaround time is a key advantage of these services. The process enables rapid production cycles, minimizing lead times from design to finished products. With automated machinery and efficient processes, manufacturers can quickly produce high volumes of parts, meeting tight production schedules. This swift turnaround time gives businesses a competitive edge by getting products to market faster, responding to changing demands, and seizing new opportunities promptly.

Exploring Different Types of Materials Used in Injection Moulding

Plastic materials

Plastic materials are the most commonly used materials in injection moulding. They offer a wide range of properties, including durability, flexibility, and resistance to chemicals and moisture. Thermoplastic polymers are popular for their ease of processing and recyclability, while thermosetting polymers provide enhanced stability at high temperatures. By choosing from a diverse selection of plastic materials, manufacturers can achieve various product characteristics, making injection moulding a versatile solution for meeting specific application requirements across different industries.

Thermoplastic polymers

Thermoplastic polymers are widely used in injection moulding due to their versatility and ease of processing. These materials can be melted, cooled, and solidified multiple times without degradation, making them recyclable and cost-effective. Thermoplastics offer a broad range of properties, including flexibility, impact resistance, and excellent chemical resistance, making them suitable for a wide variety of applications.

Thermosetting polymers

Thermosetting polymers are essential in injection moulding for their stability and heat resistance. Unlike thermoplastics, once cured, these materials cannot be re-melted or reshaped, making them permanent and durable. They possess excellent mechanical strength and dimensional stability, making them ideal for applications that require high-temperature resistance and long-term reliability, such as electrical components and automotive parts.

Elastomers in injection moulding

Elastomers play a crucial role in injection moulding, offering flexibility and resilience to products. These rubber-like materials can undergo significant deformation and return to their original shape, making them ideal for seals, gaskets, and other applications requiring elasticity. Elastomers provide excellent weather resistance, chemical stability, and low-temperature performance, making them essential components in various industries, including automotive, medical, and consumer goods.

Selecting the Right Injection Moulding Service Provider for Your Project’s Success

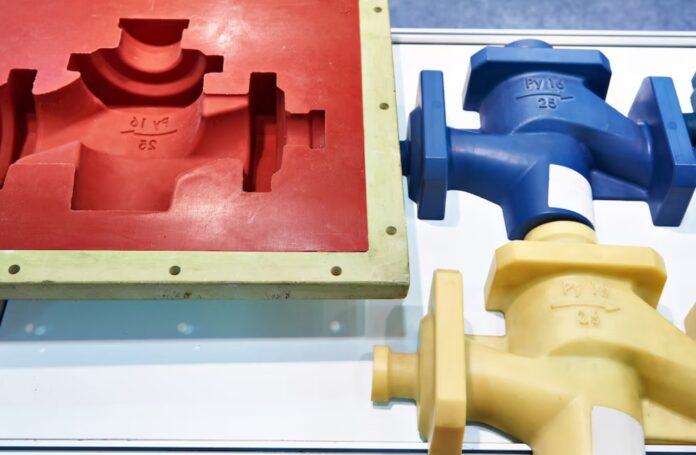

Mould making expertise

Mould making expertise is crucial when selecting an injection moulding service provider. Assess their technical skills in designing and manufacturing high-quality moulds that meet your project requirements. A provider with extensive mould making experience ensures precise and reliable moulds, translating into excellent final product quality and successful project outcomes.

Production capacity and capabilities

Production capacity and capabilities are critical considerations when choosing an injection moulding service provider. Ensure they can handle your required volume efficiently and possess the necessary machinery and technology for diverse project needs. BSA Mouldings is a reliable choice with extensive production capabilities, advanced equipment, and a proven track record of delivering high-quality plastic moulding solutions.

Quality assurance measures

Quality assurance measures are vital when choosing an injection moulding service provider. Look for certifications like ISO 9001, demonstrating their commitment to maintaining consistent and high-quality production standards. Providers with rigorous quality control processes ensure the delivery of reliable and superior products, instilling confidence in your project’s success.

Cost considerations

Cost considerations are essential when selecting an injection moulding service provider. Compare quotes from different companies to ensure competitive pricing without compromising on quality. Evaluate the overall value offered, taking into account expertise, production capabilities, and customer service. Choose a provider that aligns with your budget while delivering excellent results for project success.

Empower Your Manufacturing Business with Reliable Injection Moulding Services

In conclusion, embracing reliable and efficient services can empower your manufacturing business to reach new heights. With cost-effective production, high-quality output, design flexibility, and fast turnaround times, this versatile process offers numerous advantages. By partnering with a reputable injection moulding service provider, you can optimize production, deliver quality products, and stay competitive in the dynamic manufacturing landscape today.