There is no doubt that robots are changing the workplace. Robots are proving their worth in several industries, from automating routine tasks to assisting with more complex processes. Here are seven benefits of using robots in the workplace.

What are robots, and why are they becoming more common in the Workplace?

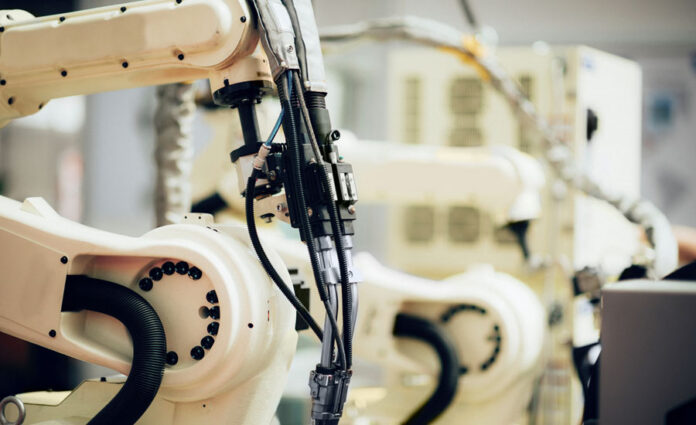

Robots are computer-controlled machines that can autonomously perform various tasks, such as manufacturing and assembly, without direct human intervention. They have become increasingly popular in the workplace because they can be programmed to perform mundane and repetitive tasks quickly and accurately with no errors. Like robotic arms in an assembly line or vacuums in a warehouse, robots have become reliable tools for businesses to increase productivity and efficiency.

The benefits of using robots in the Workplace

Here are seven top benefits businesses can achieve by using robots in their workplace.

Increased Productivity: Robots can work 24 hours a day, seven days a week, with no breaks or holidays, meaning they can increase productivity and output significantly. They can also be programmed to perform tasks more quickly than humans, allowing for greater efficiency in production lines.

Reduced Labor Costs: The use of robots can reduce labor costs as they do not require salaries or wages, nor will they incur any expenses related to vacation, sick leave, or training.

Improved Quality: Robots can maintain high levels of precision and accuracy when performing tasks. It helps improve product quality, reducing the chance of defective items entering the market.

Improved Safety: Robots can help reduce workplace accidents by taking over dangerous tasks, such as welding or cutting. They can also work in extreme environments that may be too risky for humans, such as areas with high radiation levels or toxic gases.

Reduced Errors: Robots can work with consistent precision and accuracy, resulting in fewer errors. It helps reduce product defects, unnecessary delays, and costs associated with rectifying mistakes.

Enhanced Flexibility: Robots can be programmed to perform various tasks and quickly adapt to changing production needs. They can also work in many different environments and can be used for any task requiring repetitive motion.

Increased Employee Morale: By taking over the more mundane tasks, robots can free up time for employees to focus on more complex jobs. It not only helps motivate workers but also allows them to develop their skills further.

The challenges of using robots in the workplace

Despite the numerous benefits of using robots in the workplace, some challenges are associated with them. These include:

High Cost: Robots can be expensive to purchase and maintain. It is especially true for more extensive and sophisticated models, which may require specialized training or software updates. Nevertheless, many companies have been coming out with more affordable robots to cater to small and medium businesses, an example being Danish manufacturer Universal Robots.

Inflexibility: While robots can be programmed to perform various tasks, they often cannot adjust to sudden changes in the production process. It can cause delays and other problems if the robot cannot adapt quickly enough. However, there are smart robots now that have built-in sensors and spatial awareness, and they can adapt to different changes as required.

Safety Risk: Having robots around can pose a safety risk, as they may malfunction or operate incorrectly if not correctly maintained. It is also essential to ensure robots are kept away from people and other objects to prevent accidents. A good way to mitigate this risk is to use cobots – collaborative robots – which are designed to work alongside people.

The future of robotics in the workplace

As technology advances, robots are becoming more commonplace in the workplace. They are increasingly being used to automate mundane and repetitive tasks, allowing employees to focus on higher-value activities. It can help to improve productivity and efficiency, as well as reduce labor costs.

In addition, some robots have been developed that can interact with humans and respond to voice commands. As these technologies continue to improve, robots are likely to become even more integrated into the Workplace in the years ahead.

How to Implement Robotics into Your Organization

It’s important to have a clear vision of what you hope to achieve with the technology. You’ll need to make sure that the robots are compatible with your existing systems and processes. And finally, you’ll need to create an effective implementation plan.

To get a clear vision of what you want to achieve with robotics, it’s important to consider the benefits that the technology can provide. For example, robots can help increase efficiency and accuracy in your operations. They can also help reduce costs by automating tasks or improving manufacturing processes.

Once you’ve determined the benefits, it’s time to think about how they will be implemented. The first step is to make sure that the robots are compatible with your existing systems and processes. This means ensuring that the robots are able to communicate with your computer systems and other devices as well as transfer data accurately.

After that, it’s important to create an effective implementation plan. This plan should include everything from setting up training programs for employees who will be working with the robots to creating policies and procedures for using them in your business. Overall, implementing robotics into your organization is a complex task that requires careful planning and execution. However, if done correctly, the benefits will far outweigh any challenges involved.

Conclusion

As businesses continue to face increasingly competitive markets, finding ways to improve efficiency and cut costs is of the utmost importance. Robots have the potential to revolutionize the Workplace and improve productivity, quality, and safety. They can also work 24 hours a day, seven days a week, with no breaks or holidays, allowing companies to increase their output significantly.

However, robots can be expensive to purchase and maintain and inflexible when it comes to sudden changes in the production process. Despite these challenges, robots are increasingly becoming more common for many businesses. As technology advances, they are likely to become even more integrated into our world in the years ahead.