Heat exchangers are vital components of many industrial and commercial systems. They provide a means of exchanging energy between two mediums, such as hot fluids, ambient air, or machinery. Heat exchangers are often called upon to cool or heat liquids, gases, air, and other substances in numerous industries, including heating and ventilation, refrigeration, chemical processing, and automotive.

There are a few leading manufacturers of heat exchangers that have years of experience in providing high-quality products that meet customer requirements.

Onda Manufacturing of Heat Exchangers covers everything from engineering design to assembly and testing. These products are designed with guaranteed performance levels and manufactured precisely to customer specifications. With advanced technology and experienced personnel, this type of product can provide standard and custom-built heat exchangers.

Types of Heat Exchangers and Their Applications

Heat exchangers are an integral part of many industrial processes, allowing for the efficient transfer of heat from one medium to another. Heat exchangers are commonly used in chemical processing, power generation, HVAC systems, and other applications, and they can also be found in residential and commercial applications.

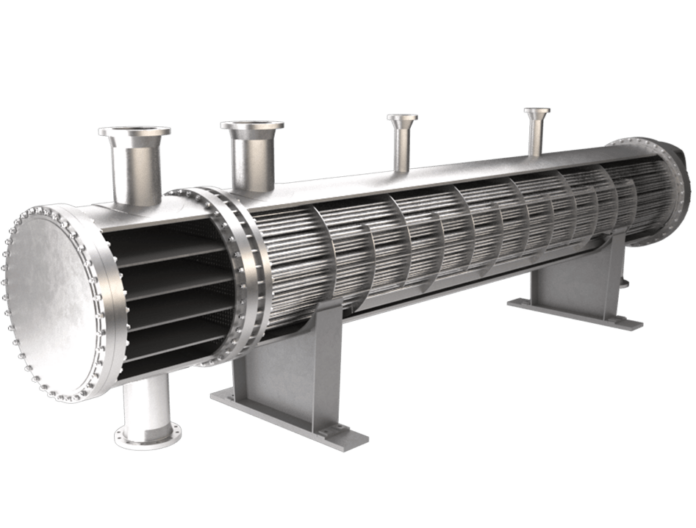

The two main types of heat exchangers are plate and shell-and-tube. Plate heat exchangers are composed of several thin, corrugated plates that are sealed together to form a compact assembly. Shell-and-tube heat exchangers consist of tubes inside an outer shell, and the two fluids flow through the tubes and around them. Due to their highly efficient design, shell-and-tube heat exchangers are commonly used for large-scale applications.

When selecting a heat exchanger, it is important to consider the application and conditions in which it will be used. Factors such as flow rate, pressure, temperature differential, and fluid properties should all be considered. Heat exchangers can also be designed to accommodate specific requirements such as fouling, corrosion resistance, and other environmental factors.

Design Considerations for Manufacturing Heat Exchangers

There are many factors to consider when designing and manufacturing heat exchangers. To ensure efficiency and performance, best practices must be followed to ensure the quality and reliability of the final product.

The first step to creating an optimal heat exchanger is to choose the appropriate materials for its construction. The material should be able to withstand the temperatures of the system and should be resistant to corrosion. Common materials used in heat exchanger construction include stainless steel, aluminum, copper, brass, and titanium.

The design of the heat exchanger must also be considered. The size and shape of the unit will determine its efficiency and performance in various applications. Depending on the application, certain features, such as fins or baffles, may be necessary to increase the surface area for heat transfer. It is also important to consider design elements like flow rate, pressure drop, and temperature differential to create a unit that meets all requirements.

In addition to design considerations, the manufacturing process must be carefully planned. This includes selecting the appropriate production methods, such as casting, welding, or machining. Ensuring that all safety protocols are followed throughout the process is also essential.

By following best practices when designing and manufacturing heat exchangers, companies can create a high-quality product that will perform effectively for years.

Quality Control in the Manufacturing Process

Heat exchangers are essential components for industrial processes and must be manufactured to a high standard to ensure they are safe and reliable. Many different best practices should be followed during the manufacturing process to achieve this.

Quality control is essential to any manufacturing process, as it helps ensure that any parts produced meet the required specifications and standards. In heat exchanger manufacturing, it is important to ensure that all equipment is calibrated correctly before use and that any problems are addressed quickly. Inspections should be conducted regularly throughout the manufacturing process to ensure all components meet the correct standards.

In addition, utilizing appropriate temperature control and monitoring systems during manufacturing can help keep temperatures within the acceptable range, ensuring that parts do not become damaged. Finally, documenting all procedures throughout the process can help ensure that each step is done correctly.

Automation and Robotics in the Production of Heat Exchangers

Automation and robotics have become increasingly popular in the production of heat exchangers. Automated systems can reduce labor costs, improve accuracy, and minimize the risk of human error in the manufacturing process. Robotics are especially useful in tasks involving repetitive motions or precision cutting, which require high accuracy.

Automation can also reduce material waste due to its ability to cut shapes and size materials with minimal waste precisely. Robots also increase safety on the factory floor by reducing the need for manual labor, which can often be dangerous.

In addition to automation and robotics, other best practices should be employed in manufacturing heat exchangers. Quality assurance processes should be rigorous and consistent, and safety standards should be strictly followed. It is also important to ensure that all parts fit together correctly and are properly aligned.

A good manufacturing process must also account for changes in temperature, pressure, or other conditions that can affect the performance of the heat exchanger. Finally, it is essential to use only high-quality materials when constructing the heat exchanger and properly maintain and inspect the equipment for any signs of wear and tear.

Conclusion

The manufacturing and production of heat exchanger products provide challenges and opportunities for businesses. Manufacturers must stay current on the latest developments as new technologies emerge to remain competitive. In doing so, best practices should be followed to ensure the highest quality, most efficient results.

When considering which technologies and processes to use when manufacturing heat exchanger products, it is important to consider various factors. For example, the environment in which the product will be used must be considered.

Different materials and methods are needed depending on whether the product will be used indoors or outdoors and other environmental factors such as temperature and humidity. In addition, the product’s size and complexity must also be considered.