The world of electronics is very complex and there are many things you need to learn if you want to understand it better. Even if you are pretty familiar with this field, there are probably some elements that you cannot clearly distinguish, which can create difficulties in your work. For example, people often mix PCB and PCBA, and sometimes even use them as synonyms, even though they are completely different things. If you’ve ever wondered what the difference is between PCB and PCBA, here’s some information on that.

What is a PCB?

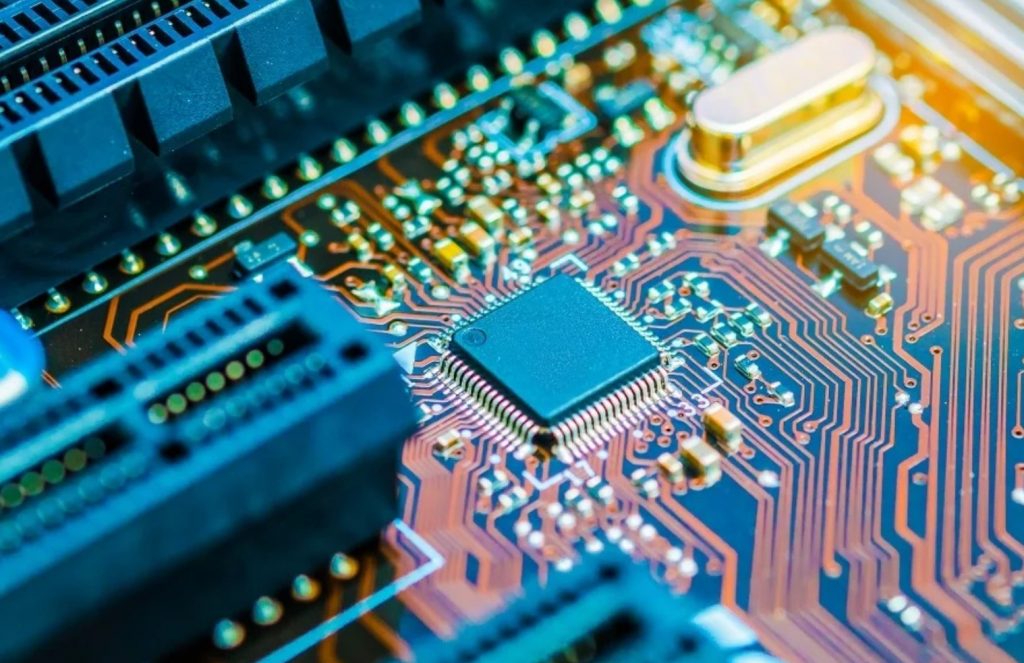

PCB is an abbreviation for a printed circuit board. It is a mechanical base that represents a carrier for various electronic components. They are connected so that they form a circuit and function together. It contains various conductive and non-conductive features. There is a conductive pattern, as well as a non-conductive substrate, which is commonly made from glass epoxy resin. PCB is made using electronic printing, hence its name. The PCB pattern can be made from a printed component, a board, or their combination. Depending on the number of circuit layers, PCBs can be classified into different groups. There are single-layer, double-layer, and multi-layer PCBs. Printed circuit boards with four or six layers are most commonly used, although they can be much more complex and contain several dozen different layers. On different layers of PCB, there are different conductors that are interconnected by screws. The printed circuit board can also be divided into various types of boards, such as rigid and flexible, depending on its properties. Basic PCBs have advanced significantly over the years and are expected to become even more complex.

Where PCBs are used?

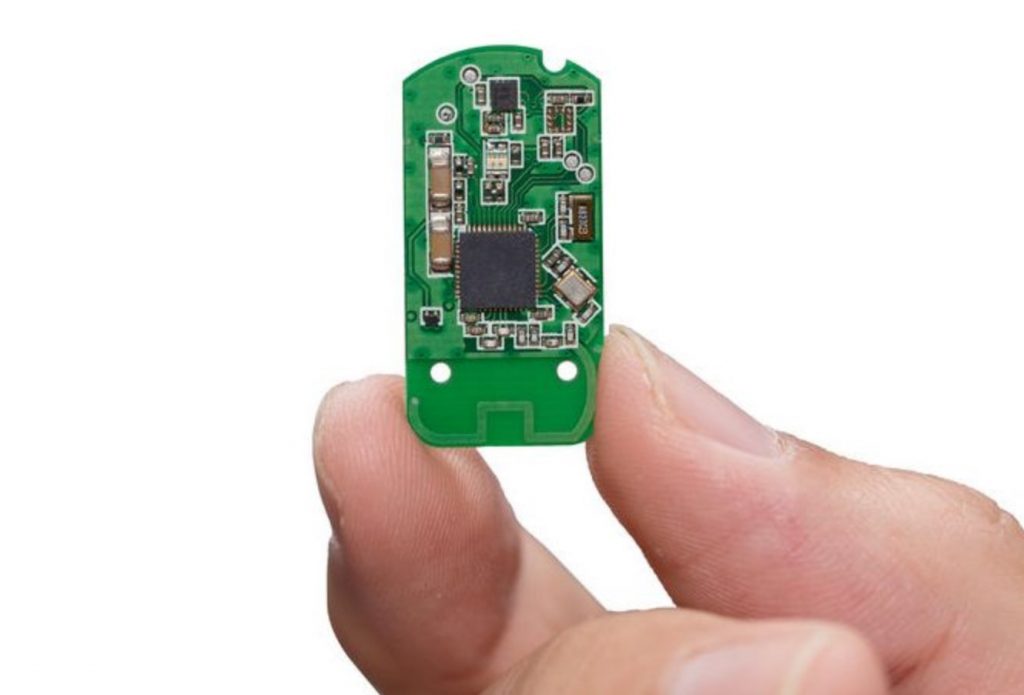

If you are wondering where PCBs are used, the answer is that this type of electronic carrier is present in a wide variety of electronic devices. Mobile phones, TVs, and cameras are just some of them. These printed circuit boards can be used in cars, as well as in the field of medicine, computers, and equipment. PCBs are often used to produce graphics cards and motherboards. The printed circuit board has a wide application in various industries because it is a carrier of electronic components and serves as a connection between them, regardless of the devices in question. The wiring is very simple and small in size, which allows small devices to be produced without any problems. In today’s modern world where technology has advanced significantly, it strives for minimalism and achieving maximum effects with minimum size, and that is what PCBs enable.

Different PCB types

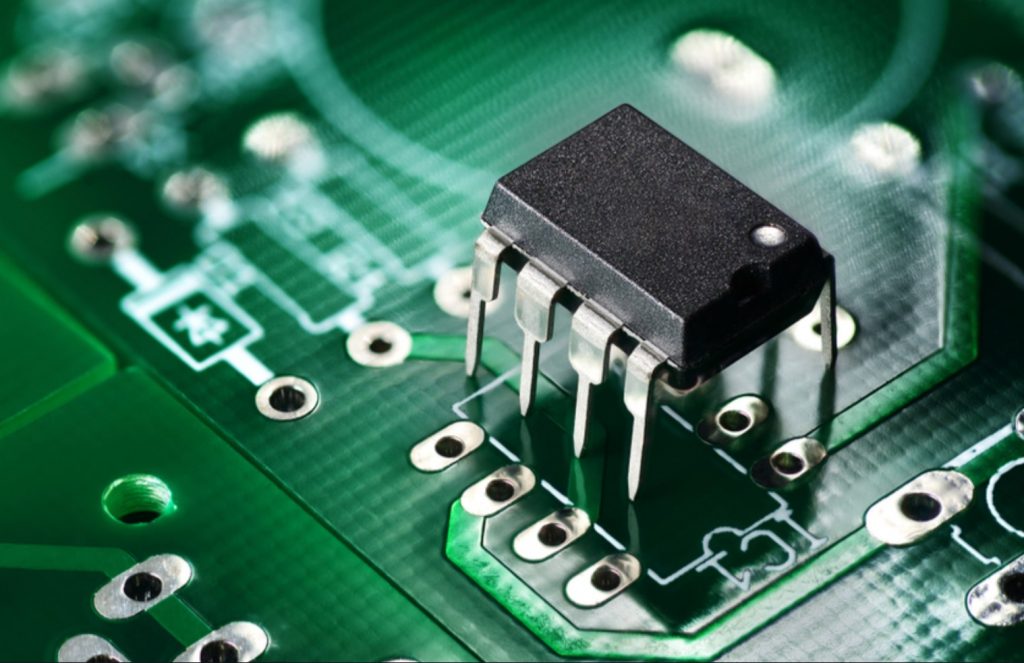

1. Single-layer

This type of PCB is very easy to manufacture and handle, so it is most commonly used. It contains only one layer of copper which is a conductive component. As you can guess, this type of PCB is very cheap, so it is used for the mass production of various devices. Some of them are radios, calculators, and others.

2. Double-layer

In the case of a two-layer PCB, the copper layer is located on both sides of the board, so it is often called a double-sided PCB. With this type of PCB, smaller size, flexibility, and greater practicality have been achieved. This type of board is most often used in phones and UPS systems.

3. Multi-layer

The multi-layer type of PCB, as its name suggests, contains many different copper layers that act as conductors. It produces a lot of heat, whose adverse effect is eliminated with help of glue between the layers. It is used in complex devices, such as satellites, medical equipment, as well as GPS, and other technologies.

What is a PCBA?

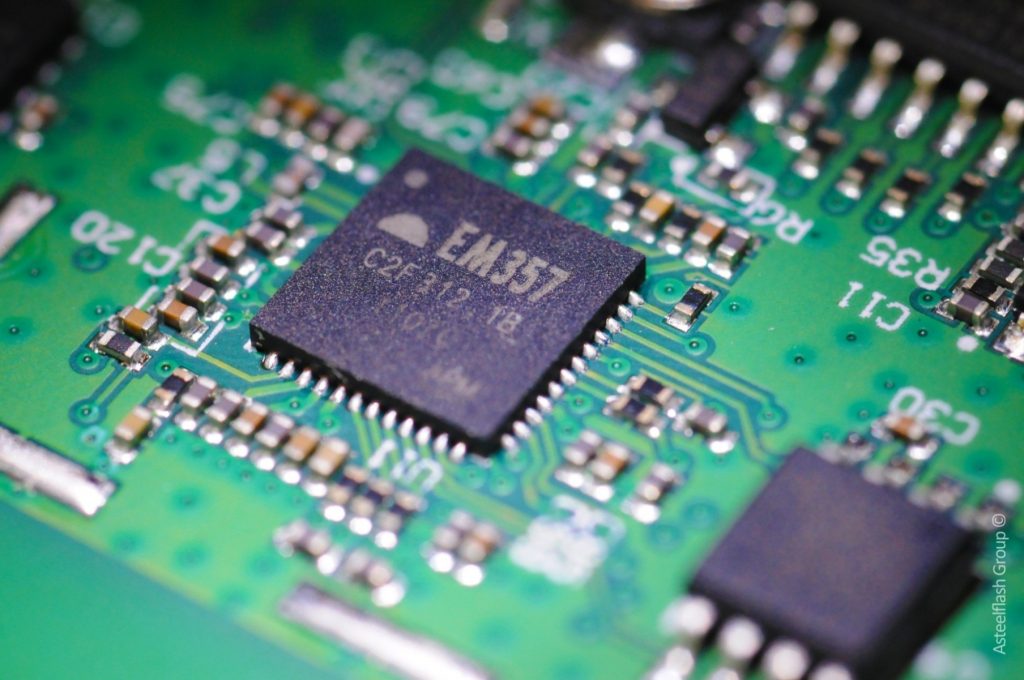

Although many believe that there is no significant difference between PCB and PCBA, this is a big mistake. PCBA is an abbreviation for Printed Circuit Board Assembly. The PCB is the basic carrier, while the PCBA is a board on which all the necessary components are mounted and which is now ready to perform its electronic function. Some of these components are resistors, capacitors, ICs, transformers, and others. The choice of components that will be included in the PCBA depends on what function the device will perform and how the design is conceived. Since a strong connection between the PCB and the components is needed in order to obtain the optimal PCB, these parts are heated together in the furnace and thus an adequate connection is achieved.

What does the PCB production process look like?

Technology through holes is used in the production of PCBA. On the PCB there are holes around which the conductive plates are placed. Electronic components that are important and that will enable the final function of the device are mounted in these holes by using SMT. Before soldering, it is necessary to glue all the components on one side of the board. In the end, you get an assembly that contains all the necessary components and is ready for further use.

The difference between PCB and PCBA

As you can see, these two terms are not the same thing and that is why it is important not to confuse them. The Printed Circuit Board is just a baseboard that is subsequently upgraded to become ready for use. Printed Circuit Board Assembly is in fact a combination of PCB and assembly and is obtained by using SMT. We can say that the PCB is only the backbone, while the PCBA is a device with electronic function. Optimal selection of PCB is important if we want to get the best result in terms of PCBA. For additional information check what experts from pcbonline.com have to say about the best PCBs.

Conclusion: Although electronics is not at all simple, experts in this field must constantly learn and improve. However, it often happens that certain terms are confused with each other, such as Printed Circuit Board (PCB) and Printed Circuit Board Assembly (PCBA). It is vital to remember that these two terms are not synonymous, but that the PCB represents a base plate that is further upgraded. After the necessary electronic components are mounted on it, it becomes a PCBA – which can now perform a certain electronic function.