Metal casting is a manufacturing process used to create complex, three-dimensional metal parts. It involves pouring molten metal into a mold, where it solidifies and takes the shape of the mold. This process has been used for thousands of years and has evolved over time to include various types of techniques.

If you are looking to manufacture a metal part, it is important to know the different types of metal casting techniques available, so you can choose the one that is best suited for your project.

Sand Casting

This is the most widely used technique in most casting services, and it involves creating a mold out of the sand. The sand is mixed with a binding agent, such as clay or resin, to hold it together and create a solid mold. The mold is then packed around a pattern, which is a replica of the desired part.

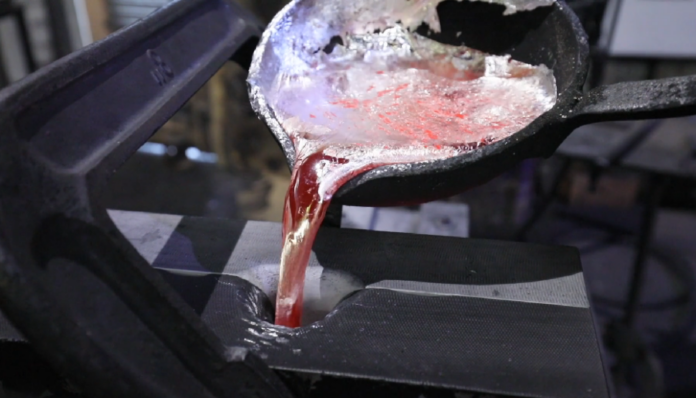

Once the mold is complete, molten metal is poured into the mold, filling the void left by the pattern. After the metal has cooled and solidified, the mold is broken apart to reveal the finished part.

Pros: Sand molding is a versatile and cost-effective process that can be used to create large, complex parts with intricate shapes. It can also be used to create parts with varying wall thicknesses and metal alloys.

Cons: It can produce parts with rough surfaces and dimensional inaccuracies. It is also a time-consuming process, as the sand mold must be created and destroyed for each part.

Investment Casting

Also known as a lost wax casting, this is a process that involves creating a wax pattern of the desired part. The wax pattern is then coated in a ceramic material, creating a mold. Once the ceramic material has hardened, the wax is melted out of the mold, leaving a cavity in its place.

Molten metal is then poured into the mold, filling the cavity left by the wax pattern. After it has cooled and solidified, the ceramic mold is broken apart to reveal the finished part.

Pros: This method can produce parts with excellent surface finishes and dimensional accuracy. It is also capable of producing complex shapes and intricate details.

Cons: It can be a costly process, due to the time and labor involved in creating the wax pattern and ceramic mold. It is also not suitable for high-volume production, as the wax pattern must be created for each part.

Die Casting

Die casting is a process that involves creating a mold, called a die, out of metal. The die is then clamped together, and molten metal is injected into the cavity created by the die. After the metal has cooled and solidified, the die is opened, and the finished part is ejected.

It is typically used for high-volume production of small to medium-sized parts.

Pros: It can produce parts with excellent surface finishes and dimensional accuracy. It is also a fast and efficient process, making it suitable for high-volume production.

Cons: This method is limited to small to medium-sized parts due to the size constraints of the die. It is also a costly process, as the die must be created before production can begin.

Gravity Casting

Gravity casting, also known as permanent molding, is a process that involves creating a mold out of metal. The mold is then heated to a specific temperature, and molten metal is poured into the mold. After the metal has cooled and solidified, the mold is opened, and the finished part is ejected.

Gravity casting is typically used for the high-volume production of small to medium-sized parts.

Pros: It is a fast and efficient process, making it suitable for high-volume production. It can also produce parts with good surface finishes and dimensional accuracy.

Cons: It can produce parts with porosity and other defects, as the metal is subject to turbulence and air pockets during the pouring process. It is also limited to small to medium-sized parts, as larger parts can be difficult to remove from the mold and may cause the mold to deform.

Centrifugal Casting

Centrifugal casting is a process that involves pouring molten metal into a spinning mold. The spinning motion of the mold creates centrifugal force, which distributes the molten metal evenly throughout the mold, creating a dense and uniform part.

It is typically used for cylindrical parts, such as pipes, tubes, and rings.

Pros: Centrifugal casting can produce parts with excellent material properties, including high density, uniformity, and strength. It is also a cost-effective process for producing high-volume cylindrical parts.

Cons: It is limited to cylindrical parts, and it can be difficult to control the wall thickness and other dimensions of the part. It is also a time-consuming process, as the mold must be spun for a specific amount of time to achieve the desired material properties.

Continuous Casting

This is a process that involves pouring molten metal into a water-cooled mold, which continuously extracts the heat from the metal and solidifies it into a continuous strand or billet. The strand is then cut into the desired length and shape.

Pros: It is a cost-effective process for producing high volumes of metal. It can also produce high-quality, uniform material with consistent dimensions.

Cons: Continuous casting is limited to producing long lengths of metal, and it can be difficult to produce complex shapes or parts with intricate details. It is also a time-consuming process, as the metal must cool and solidify before it can be cut into the desired length and shape.

Which Process is Best for Your Project?

Choosing the right metal casting process for your project depends on several factors, including the size and shape of the part, the required material properties, the desired surface finish, and the volume of production. All the methods are described above so carefully read through the pros and cons of each one to decide which one is right for you.

Wrapping up

In conclusion, understanding the different types of metal casting processes available is crucial for selecting the most suitable method for your project. Each process has its own advantages and disadvantages, and the right choice depends on your specific requirements. Whether you are producing a large, complex part or high-volume production of small parts, there is a metal casting process that can meet your needs.