The frozen food industry is booming. Over the years, it has steadily increased in popularity, both as consumer demand rose and as technology improved. Nowadays, choosing the freezing method, and then the exact machinery to manage freezing in your business, is no easy task. With a wide variety of approaches, it’s hard to keep track of what the best technology for your business may be. That’s why this article delves into the intricacies of choosing the ideal freezing machine for your business, which will help you decide.

The basics

To start us off, what freezing technologies are there? While modern freezing approaches differ individually, three broad categories can be seen:

- Top-quality freezing methods

- Classic freezing methods

- Cold storage freezing

Each has its unique advantages and disadvantages, and the one most suitable for you will heavily depend on your business strategy and goals. For instance, while the best freezing methods produce the best results, it’s no secret that they’re slightly more expensive. In a similar vein, cold storage is one of the most affordable freezing approaches and can be great when starting, but the quality of the frozen product is comparatively lower.

Importantly, compared to older freezing methods, new freezing approaches that offer the best possible result focus on one key aspect: freezing speed. Regardless of the freezing method, the quicker the freezing process happens, the better the fresh color, texture, smell, and taste are preserved. The difference between the freezing process lasting for a few hours or minutes is night and day in terms of frozen product quality.

When choosing the right freezer for the job, make sure you keep in mind your customer. Nowadays, there is a large swathe worldwide of well-to-do middle-class families looking for healthy, convenient, yet not exceedingly expensive fruits and vegetables. Frozen products are uniquely appealing, as long as they’re of high quality, and customer outlets have noted this.

High-quality freezing methods

Under this category, we can differentiate Liquid Nitrogen freezing and IQF Freezers with impingement freezing, among others. Here’s a short description for each one:

- Liquid Nitrogen freezing—the product is sprayed with or dipped in nitrogen and is then transported on a belt towards outfeed. This approach is perfect for low-capacity lines, and is usually used for high-value products as the operational costs are very high. Unfortunately, this is also its downfall, as the nitrogen costs are extremely high and challenge the profitability of the business.

- With high food safety, low dehydration, and minimal maintenance requirements, it is still an attractive choice for top-of-the-shelf frozen food production. However, working with liquid nitrogen suppliers is tricky because of minimum consumption requirements and year-long cancellation notices.

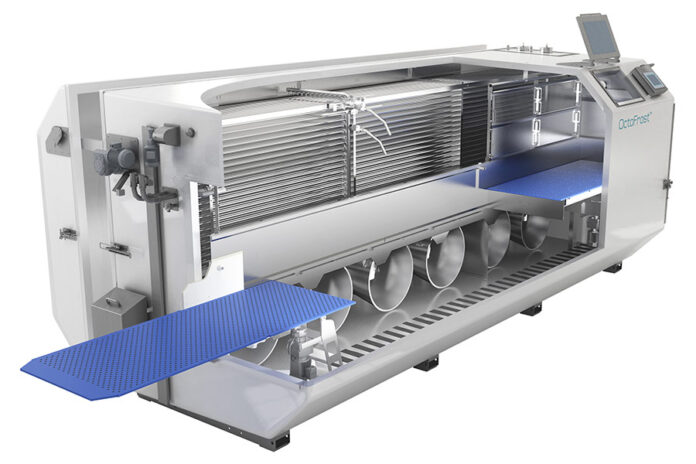

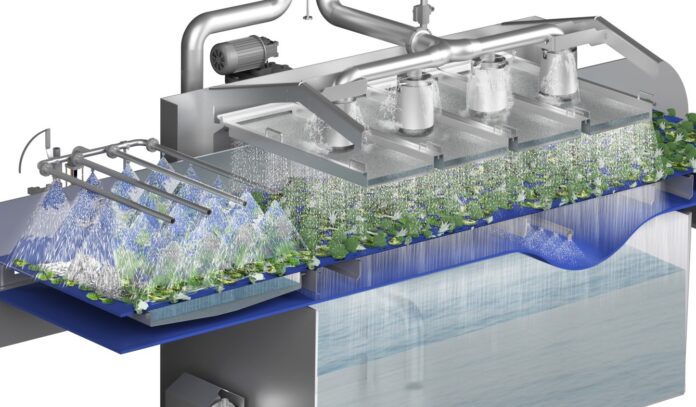

- Impingement freezing—the product is transported through the Freezer, where it is blasted with jets of freezing air from top and below. This is a highly efficient approach and ideal for flat or round products. However, it works well with many foods. The freezing is extremely quick, and dehydration is kept to a minimum, while modern machine designs allow for fast cleaning methods. The challenge with this method is low capacity, however the freshly released Multi-Level Impingement freezer, which is designed on 3 belt levels – is successfully solving the capacity issue.

- The food safety is medium, except for our quick-freezing machine, as it uses patented bedplate technology that replaces conveyor belts and supplies food safety far beyond industry regulations. With reliable service, it is highly effective for products that are smaller or can be easily separated into smaller pieces.

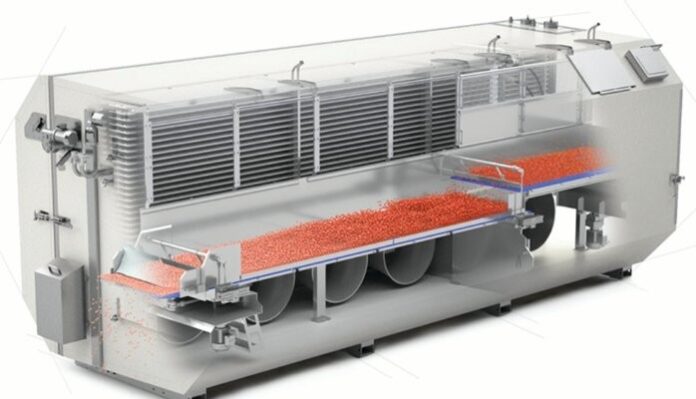

- Fluidized IQF tunnel freezing—functioning by creating complex aerodynamic flows, which can be adjusted on the go, creates optimal freezing conditions. Fluidized freezing happens extremely quickly, can be done in very high volumes and is better at preserving the shape of the product.

- High capacity: to serve as an example, our IQF Freezer can freeze approximately 3 tons of food in around 8 minutes. The adjustable airflow and air pressure makes it easier to arrive at a frozen product in perfect condition, and the low dehydration ratings make it better at remaining profitable.

Classic freezing methods

These methods have been used reliably for a long time, and while they’re not as high performance as previously discussed approaches, they provide a solid freezing experience. Here, we can differentiate between spiral freezing, block and pellet freezing.

- Spiral freezing—uses a curved belt inside the freezer to pass the products through and freeze them. Usually designed around big surface products, because of its usage of conveyor belts, its food safety is medium and there is some difficulty in maintenance, which may mean added costs.

- Certain kinds of products, such as meat, will become imprinted with the belt’s surface and it performs worse for smaller products.

- Block freezing—products are placed in cooled metal boxes and then frozen. This approach has no dehydration and minimal maintenance requirements. However, it comes at the cost of damaging the products’ structure and takes hours to one day to freeze.

- Pellet freezing—used for sauces. It freezes them using freezing air and contact with the bottom surface where the sauces are placed, sawing them off into pellets by the end. It requires high maintenance and can process large volumes of liquids, but its appearance is understandably damaged by the end.

Cold storage freezing

One of the oldest tricks in the book, the products are simply left in specially designed refrigerated chambers. Here, we can differentiate between forced-air cold storage and tunnel-pushing cold storage.

- Forced air—products are placed in trays and later on a rotating wheel, where fans circulate frigid air over them. Hard to automate and may cause significant dehydration, with high maintenance costs. It also has a high environmental footprint.

- Tunnel-pushing—trays with the product are pushed through cold storage, often by a hydraulic cylinder. The slower cold storage freezing method is similarly hard to automate and has high maintenance costs.

We recommend Octofrost’s machinery for those left interested in high-quality frozen product processing. Their IQF freezer prices are affordable when considering the short return on investment, and the unique bedplate technology guarantees that food safety and maintenance costs will never disappoint. Additionally, the high efficiency and saving possibilities may mean more money saved in the long term, compared to other approaches.

Individual quick-freezing has become a market staple, and products frozen under this approach have done well in global markets. With no end in sight to high-quality frozen food consumption, this appears to be a long-term investment worth making.