Do you often get confused about the materials used in PCB manufacturing? Well, you don’t have to worry. We have prepared a complete list of materials so that you can understand them in detail. You might already know some of them. However, it is essential to gain some knowledge of every material.

Printed circuit boards are helpful in many ways. They are present in almost every electronic device. The demand for Printed circuit boards has always been higher. Many electronic device and equipment manufacturers need Printed circuit boards for the processes. There are various shops where you can get PCB online. One of the most reliable websites is www.pcbonline.com.They offer high-quality PCB to their customers. You can visit the site to know more about the company.

Without Printed circuit boards, no electric device can perform well. They are essential to carry the supply to different parts of the device. We will also discuss some advantages of using them in this article. Now, without wasting time, let’s find out the materials used for producing PCB.

What are the common materials used in PCB manufacturing?

The most significant things needed to make a Printed circuit board are as follows-

- Substrate- Do you know what substrate means? It is the material of the PCB body. Different plate codes are available, and the most popular substrate is FR4. Manufacturers prefer it more because it has unique features. They believe that the FR4 substrates can do better than other ones due to their different characteristics. There won’t be any problems with the electronic equipment if the Printed circuit board has FR4 substrate. FR4 laminates and prepreg are produced by using glass cloth and epoxy resin. They are available at a low price in the market. These components help improve the overall performance of the circuit board. FR4 is used in the production of computers and communication equipment.

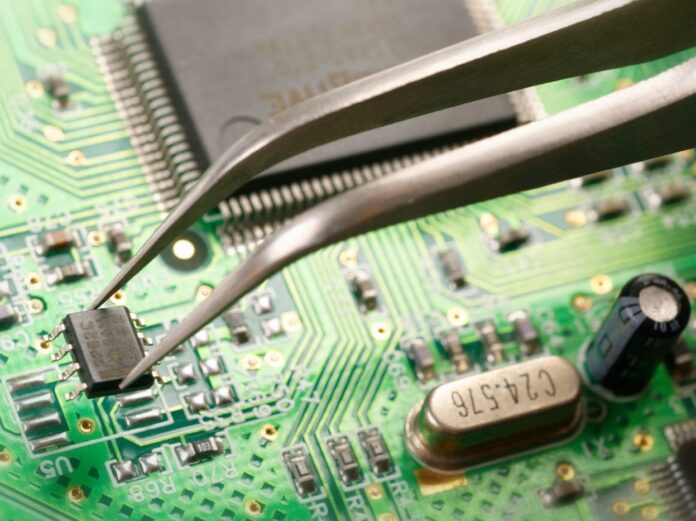

- Copper foil- Copper foil is another essential thing used in making the Printed circuit boards. It works as a conductor of electric supply on the substrate. There are two techniques through which copper wire is made- Electrolysis and calendering.

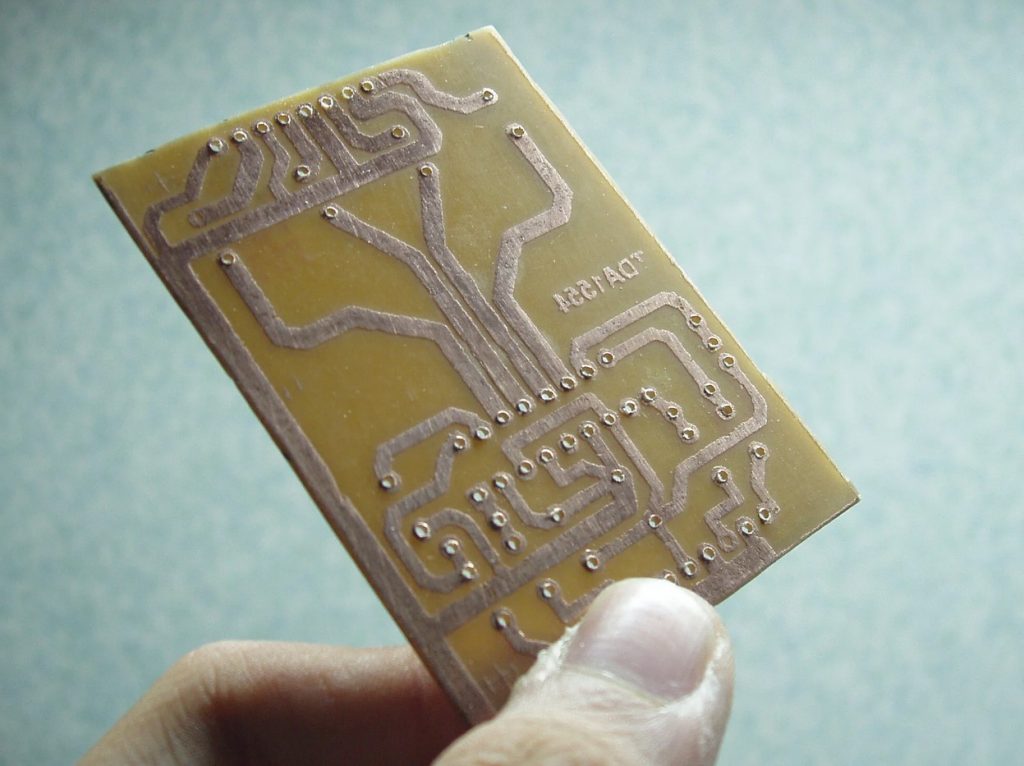

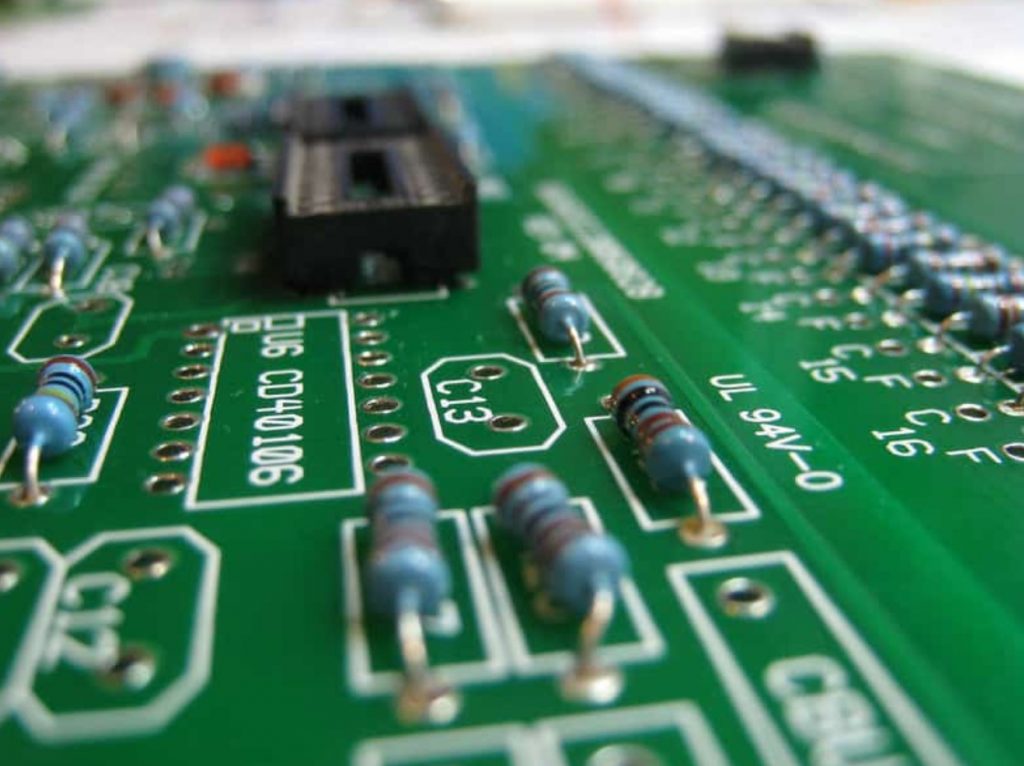

Source: Instructables - Solder Mask- The Solder mask helps protect the copper on the PCBs. There are various reasons for which the solder mask is significant. Sometimes, problems like oxidation, electrical shocks, and dust or contamination occur in the circuit. These problems contribute to making the PCB less effective in electronic devices. So, a solder mask is necessary to prevent the Printed circuit board from this serious issue. The mask is available in various colors like black, white, red, and more. The procedure of applying it on the panel is pretty simple. The first step is spraying it on the panel. Then it is formed in the pattern and gets dried in the end. One has to keep in mind some things before going into the process of soldering. So, one should research more precisely to avoid any mistakes.

- Prepreg (PP)- PP is beneficial in connecting the inner layer. It also provides insulation. It is considered a raw material in making Printed circuit boards. In other words, one can say that it is the substrate sheet when it is at the b-stage. There are different types of PP. One has many options regarding prepreg. You can study about every one of them to gain extensive knowledge.

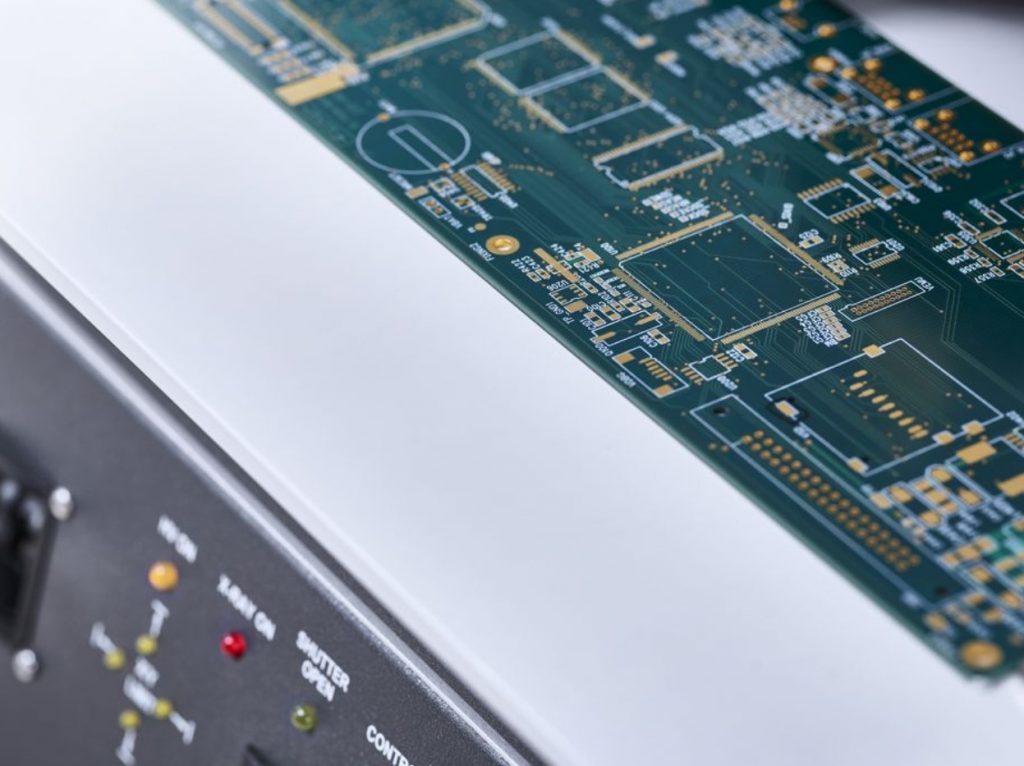

Source: Fischer Technology - Dry Film- You might already have heard about dry film. It consists of a resin substance that is responsible for a photochemical reaction. The dry film includes three layers. The protection is done by the photosensitive layer that is present between two layers. You will find two types of dry film. One is photopolymerization and the photodecomposition. Both of them have different characteristics. Photopolymerizable usually hardens due to the irradiation of light, so it becomes insoluble in water.

- Negative Film- Because of the negative film, the Printed circuit board’s design is possible. The first thing everyone does for getting a PCB from a factory is transmitting the circuit diagram. This diagram then transforms into a negative film. So, there is massive importance of negative film in the manufacturing of PCBs.

Source: Electronics-Lab

What are the benefits of using Printed circuit boards?

As we discussed earlier, PCBs are essential for every electronic device. There are plenty of benefits of using them. They are as follows:

- Size is compact with almost no wires- The size of the PCB is compact and does not cause bulkiness in the electronic systems. All the components in it are pretty small. They easily get connected without the use of wires. When there are many wires in a device, it creates chaos. If damage occurs in the system, it won’t be easy to repair it.

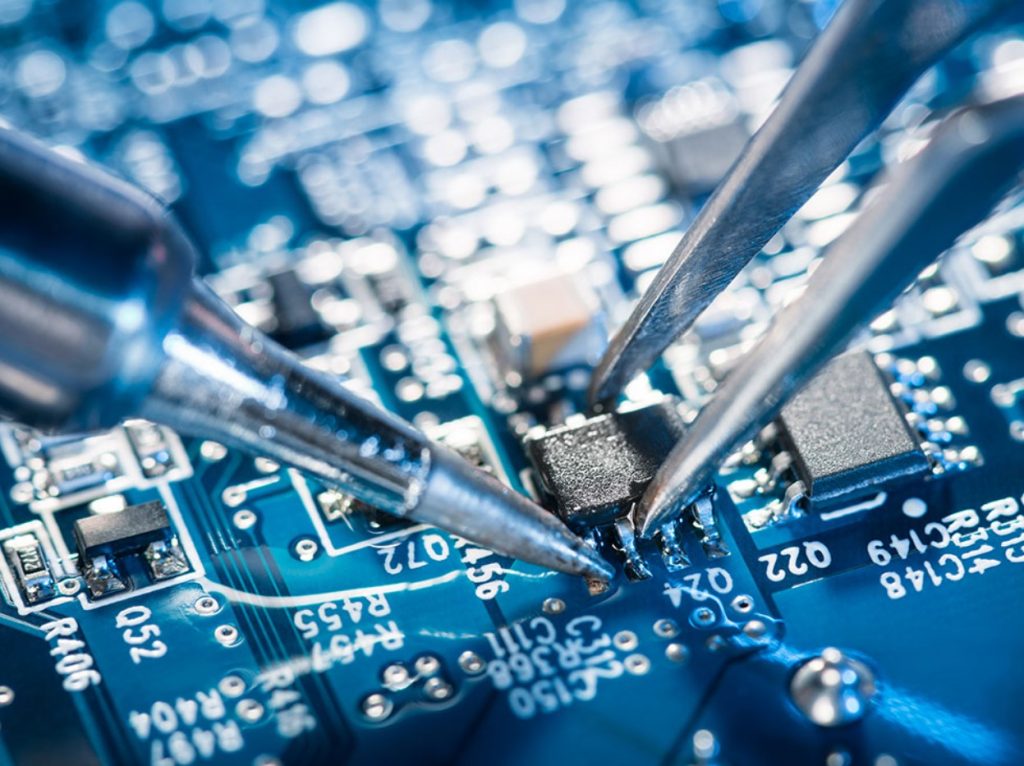

- Easy to repair- In the printed circuit boards, solving any issue is pretty simple. On the contrary, if there are only wires in the electronic equipment, one has to face many difficulties. These boards consist of labeled components. So, the process of installing the device and repairing the damage is more convenient.

- Saves a lot of time- The whole process of connecting all the PCB components saves a lot of time. If we talk about other circuit connections, it is not an easy task to assemble various components. Due to this reason, they are more beneficial than other ones.

- Movement is not possible- When it comes to Printed circuit boards, the movement of the components is not possible. You may ask, why? Well, it is due to the solder mask that fixes all of them permanently. As a result, there won’t be any problems regarding it.

- Loose connections- You might have seen that wired circuit boards can have problems like loose connections. But in PCBs, all the connections are made with copper tracks. There is no chance of loose connections.

Final Thoughts

In conclusion, we would like to say that the materials used in the manufacturing of PCBs are pretty complex to understand. However, one can easily do it by researching them. We hope this article helped you in finding all the necessary information regarding PCB and its materials.